Our 3D CAD interface solutions

In many companies in plant and mechanical engineering there are changes every day; these changes need to be updated in 2D flow diagrams and 3D piping models in various disciplines such as electrical, instrumentation and control.

These specialists often work independently of each other and find it difficult to get a clear overview of the entire project. This leads to a planning risk due to the potential inconsistency of data and extra effort in communication. Changes in reports, drawings, and 3D models must also be made manually by highly qualified engineers.

These interdisciplinary additional efforts have to be minimized. The problem is that most of the disciplines work with their CAD solution and no communication takes place between 2D P&ID and EMSR.

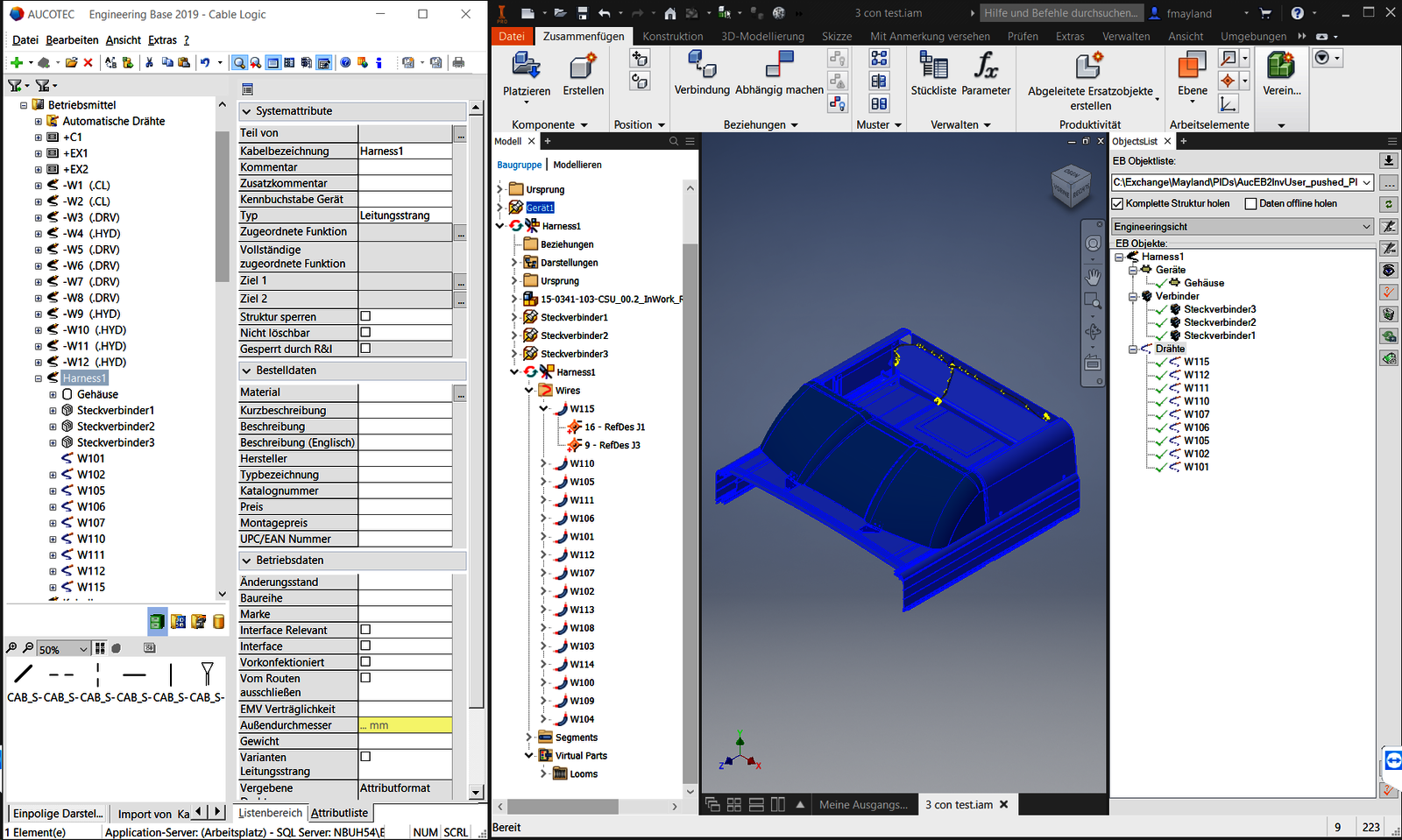

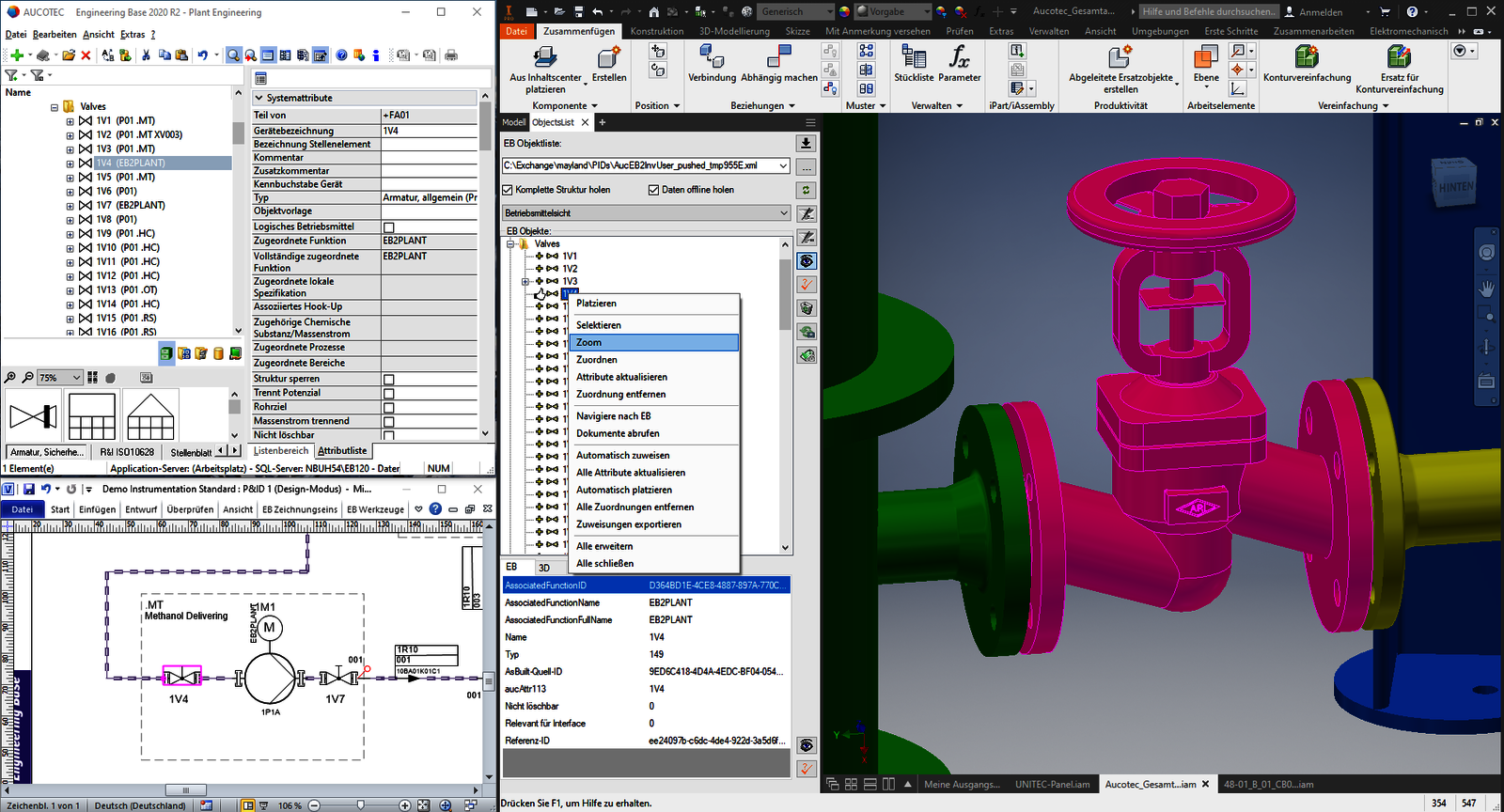

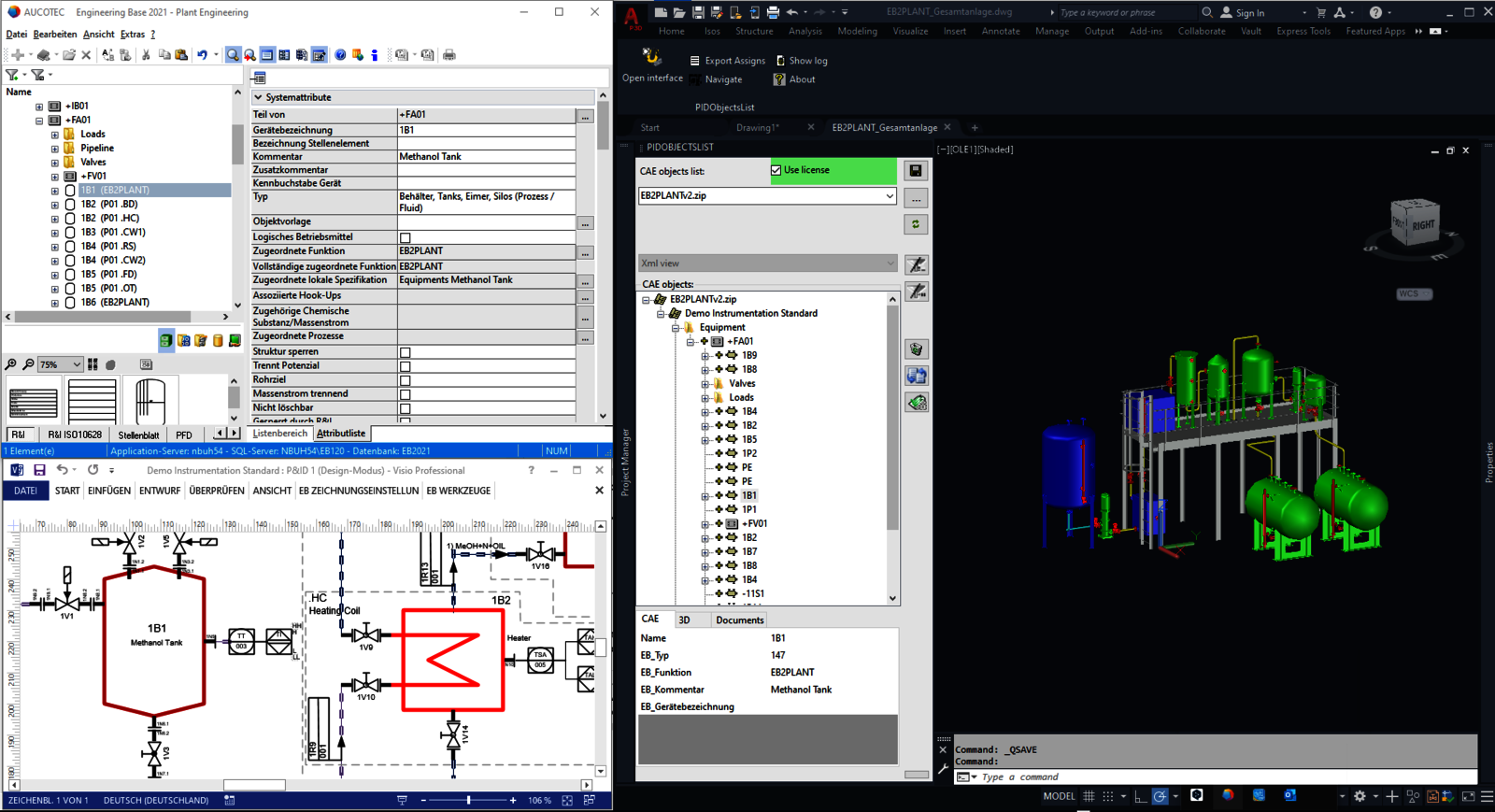

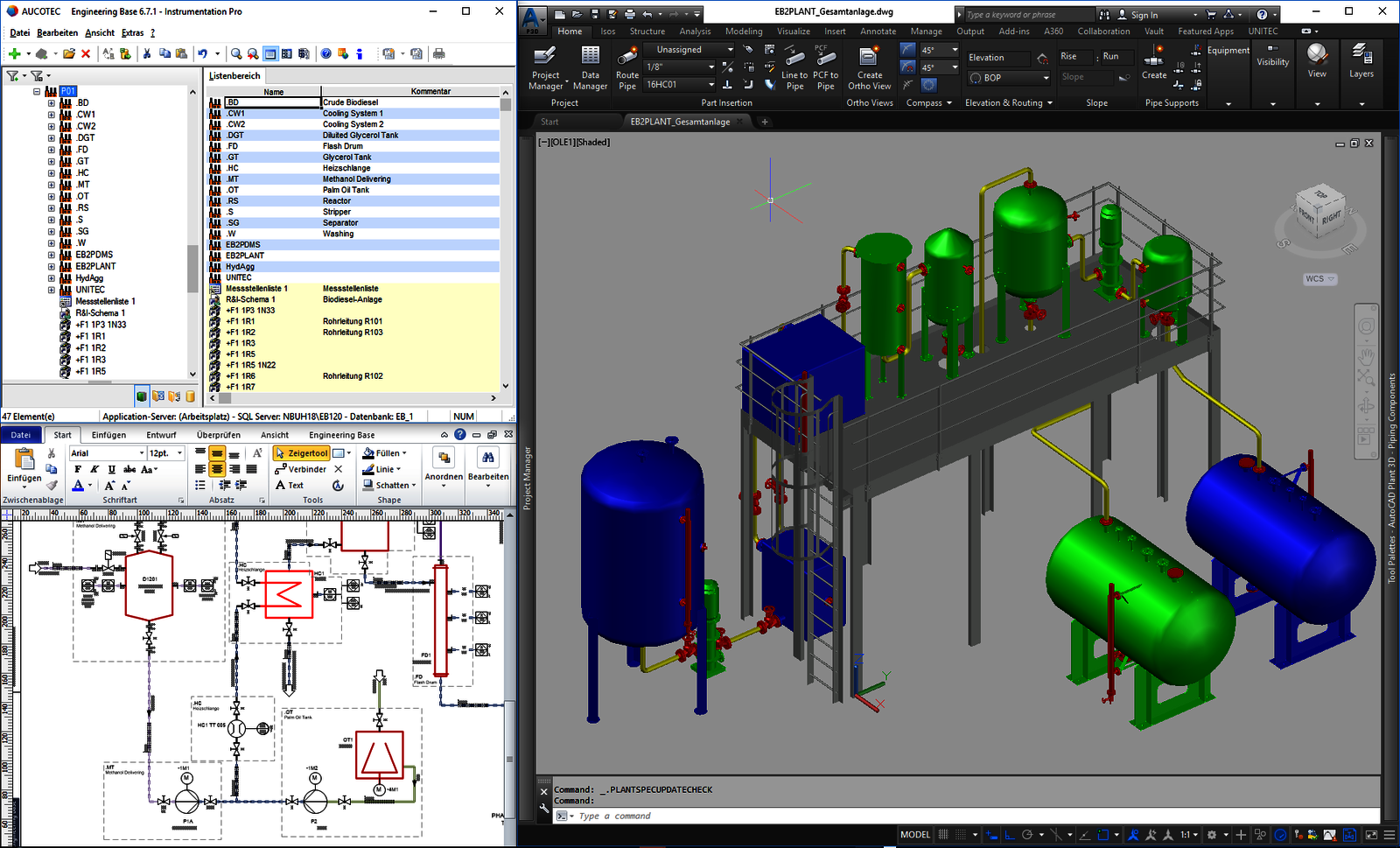

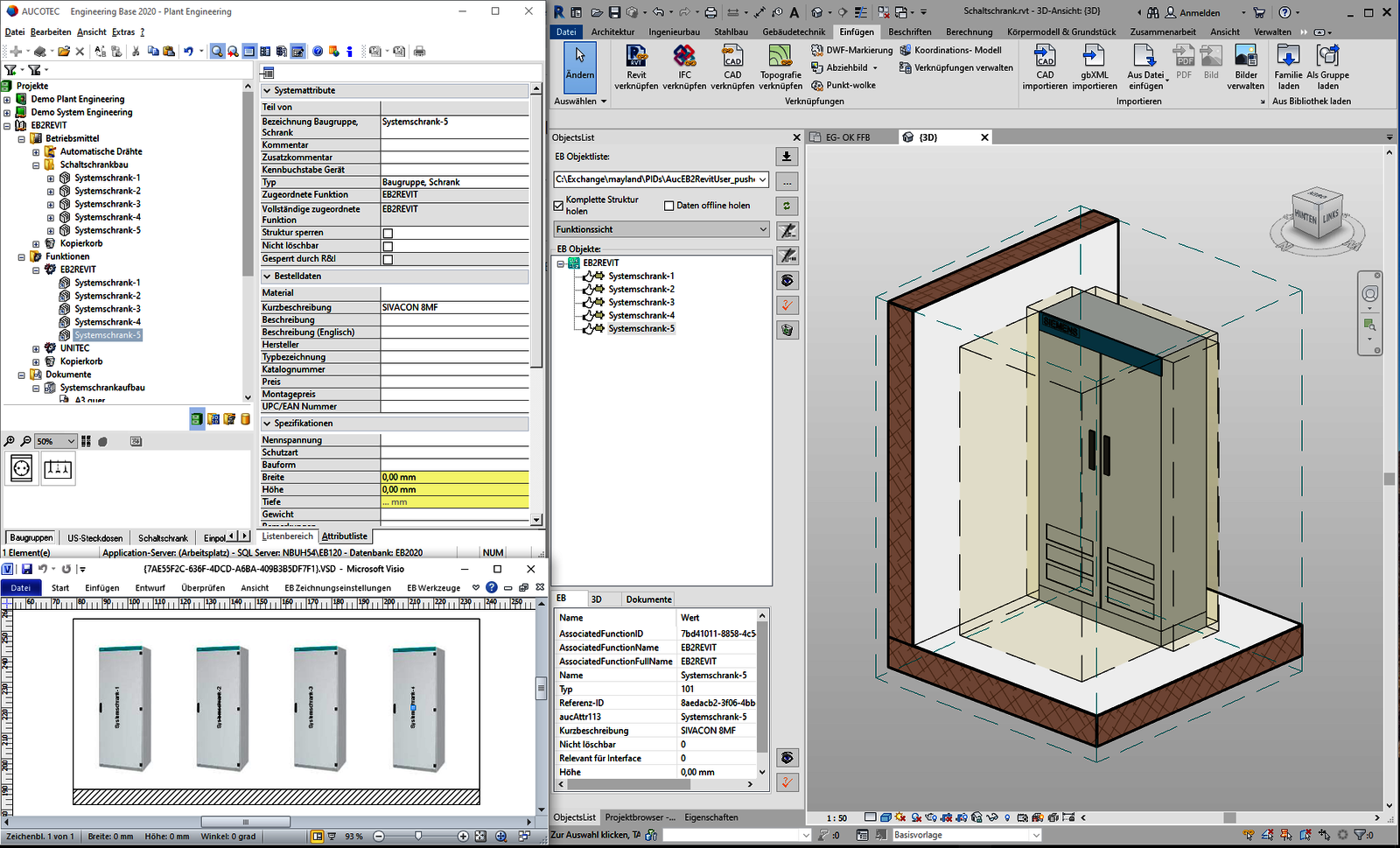

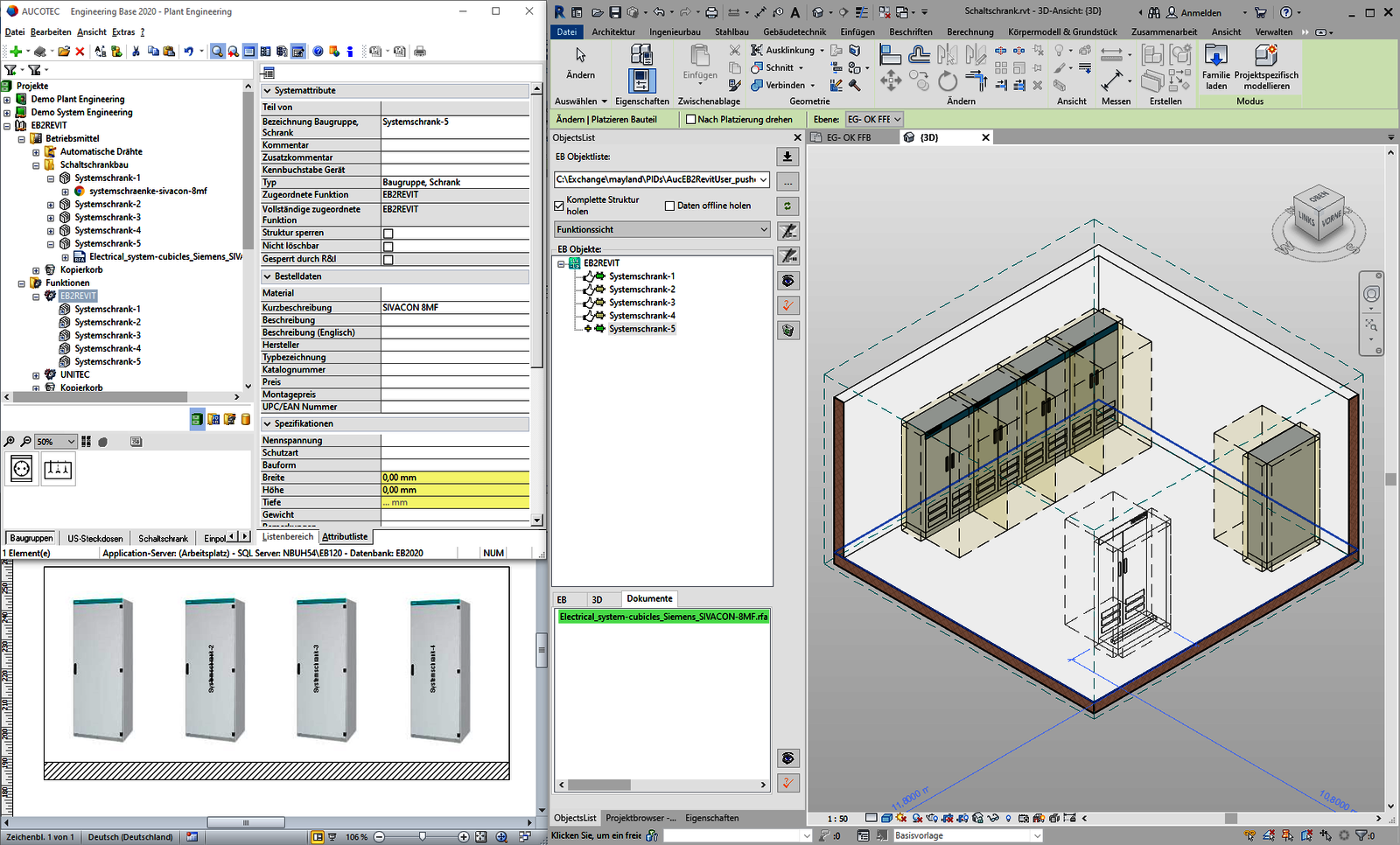

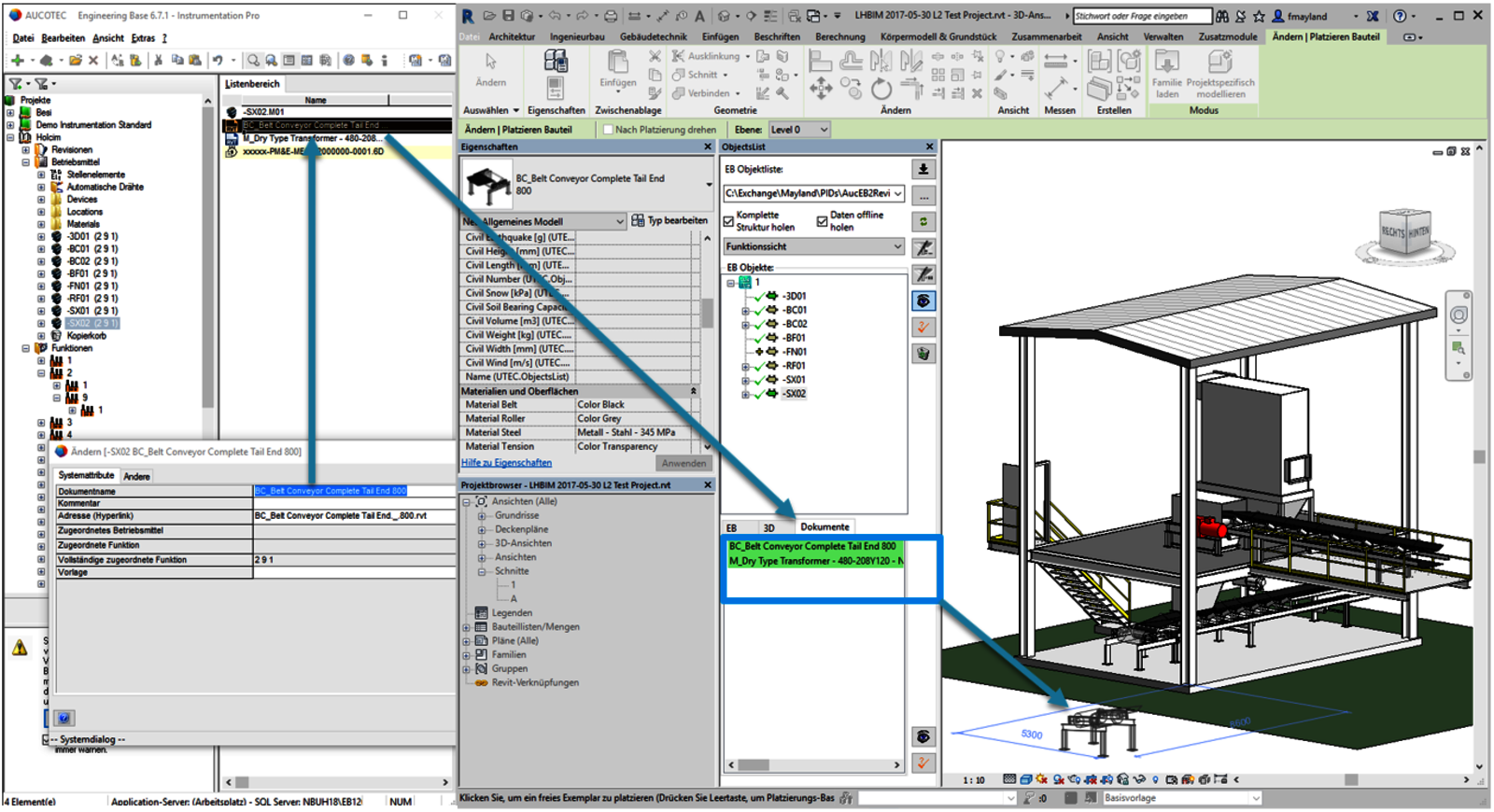

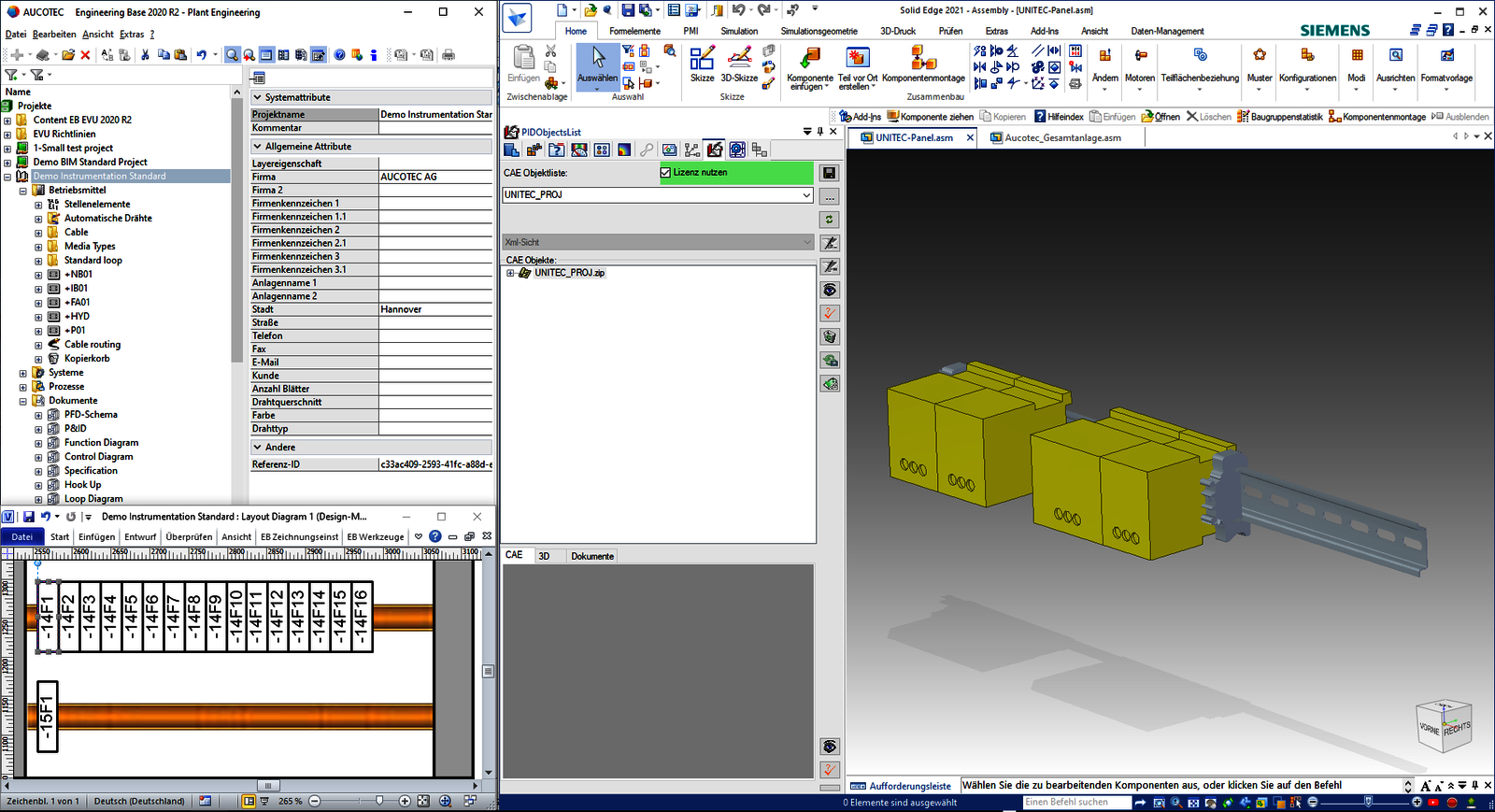

Together with AUCOTEC, we have developed an independent platform that effectively combines 2D Engineering Base and the 3D plant design system AutoCAD Plant 3D. From the plant structure to the object properties, all relevant information from the 3D world is linked with that from the flowsheet and detail engineering.

The coupling is based on the data defined in the R&I of the apparatus, vessels, instruments, consumers, pumps and valves. The solution has huge potential for all plant designers who think outside the box and are tired of duplicate work. Those who also target EMSR and 3D to the right and left of the flow diagram and want to connect their processes to work faster, better and more cost-effectively will finally find what they are looking for here.

Regardless of the specialized knowledge of each other's disciplines, the various experts, from the process engineer to the mechanical, I&C and electrical engineering profis, work with all the relevant data and obtain a unique overview of the complete plant.

Your advantages when using:

- Reduction of additional interdisciplinary efforts

- Linking of all relevant information

- Faster, higher-quality and cost-saving work